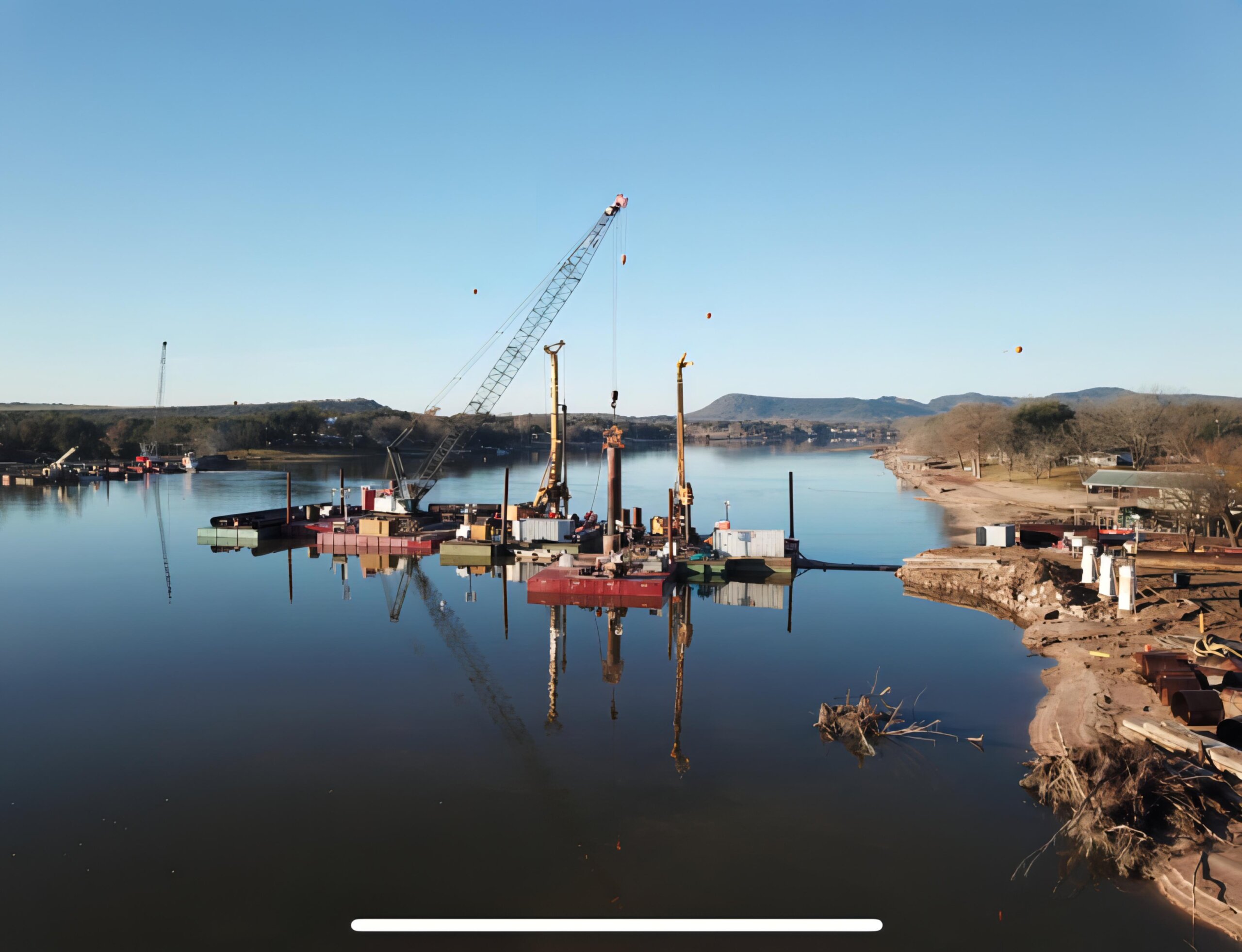

A.H. Beck installed drilled shafts for an emergency contract to rebuild the RM 2900 bridge washed away by the floodwaters on the Llano River arm of Lake LBJ in Kingsland, Texas.

The Texas Department of Transportation awarded an emergency contract to rebuild the RM 2900 bridge that was washed away in rushing floodwaters on the Llano River arm of Lake LBJ in Kingsland on Oct. 16, 2018. This was the largest flooding event in that location since 1935. Built in 1969, the RM 2900 bridge was designed to withstand a 50-year flood event. At the height of the flooding, the river was discharging an estimated 290,000 cubic feet of water per second. The new bridge was designed with 48 – 48 inch diameter drilled shafts that extend down 110’ below the surface with up to 30 feet of socket into Texas Pink Granite. The granite has an unconfined compressive strength of 32,000 psi. 9 of the 48 shafts had to be constructed under 40’ of overhead clearance due to high voltage power lines crossing the north end of the bridge. 33 of the shafts were installed from sectional barges in up to 25’ of water. A H Beck and Capitol worked around the clock to accelerate the construction. The shafts were drilled using A H Beck built ORUGA drill rigs, one producing 185,000 foot pounds of torque and a larger machine that produces 265,000 foot pounds of torque. The rock sockets are being excavated with a reverse circulating cluster drill that utilizes 10 – 8” pneumatic hammers. The air tooling took 5 air compressors producing 5850 CFM of air while burning 110 gallons of fuel every hour.